I remember my first time with glaze formulation in pottery class. It was thrilling to see a plain clay turn into a colorful masterpiece.

Making ceramic glazes is all about chemistry. Knowing the chemistry lets potters explore new ideas and get the look they want.

In this article, we’ll explore Ceramic Glaze Chemistry. We’ll cover the main ideas and methods to help you master glaze making.

Key Takeaways

- Understanding the basics of glaze formulation

- The importance of chemistry in creating ceramic glazes

- Techniques for achieving desired aesthetic effects

- Tips for experimenting with different glaze formulations

- Common challenges and solutions in glaze formulation

Introduction to Ceramic Glaze Chemistry

Ceramic glaze chemistry is key to a piece’s look and durability. As I explore ceramics, learning about glaze chemistry has been vital. It helps me as an artist.

What is Ceramic Glaze?

Ceramic glaze is a blend of raw materials. When applied to ceramics and fired, it forms a glassy surface. This surface makes the pottery look better and is safe for food.

The mix of glazes includes silica, alumina, and fluxes. These elements work together in a complex way.

Importance of Ceramic Glazes in Art

Ceramic glazes are vital for artistic expression. They let artists create many colors, textures, and effects. By changing the glaze’s chemical makeup, artists can make unique pieces.

Glazes do more than just look good. They also make ceramics water-resistant and more durable.

Learning about ceramic glaze chemistry opens up new possibilities. Knowing how glaze composition works lets artists control their creations better. This leads to more consistent and creative results.

The Composition of Ceramic Glaze

To master ceramic glazing, you need to understand the basic parts of glaze making. Ceramic glazes are made from different chemical elements. When mixed and fired, they create the look and function we want on ceramics.

Key Ingredients in Glazes

The main parts of ceramic glazes are fluxes, silica, and alumina. Fluxes are key because they make silica melt easier. This helps the glaze flow well during firing. Silica is the glass maker, giving the glaze its structure. Alumina keeps the glaze from running off the ceramic during firing.

How these parts work together is very important. For example, the silica to alumina ratio affects the glaze’s strength and look. Knowing how they interact helps in making good glaze recipes.

Role of Fluxes, Silica, and Alumina

Fluxes like sodium, potassium, and calcium are vital. They lower the glaze’s melting point, allowing for a glassy surface at lower firing temperatures. Silica is key for the glassy phase, and alumina keeps the glaze strong and prevents it from changing.

The mix of these ingredients decides the glaze’s look, melt, and durability. By adjusting the amounts, artists can get many different effects. This can range from shiny and clear to dull and thick.

Understanding Additives

There are also additives in glaze recipes for special effects. These include colorants, opacifiers, and texture modifiers. Knowing how these additives work with the main ingredients is important for the glaze’s final look and feel.

For instance, adding certain metallic oxides can bring in colors. Opacifiers like zirconium oxide make the glaze more dense. Choosing and using these additives carefully is key to getting the desired result.

Types of Ceramic Glazes

Ceramic glazes come in many types, from glossy to matte, and transparent to opaque. This variety lets artists try different looks in their work.

Glossy vs. Matte Glazes

The finish of a glaze changes how a piece looks. Glossy glazes are shiny and make colors pop. Matte glazes are flat and add a quiet beauty.

Transparent and Opaque Glazes

Glazes can also be transparent or opaque. Transparent glazes let the clay body show through, adding depth. Opaque glazes cover the surface with a solid color.

Specialty Glazes: Crackle and Celadon

There are also specialty glazes with unique effects. Crackle glazes form fine cracks for a textured look. Celadon glazes have a soft green color and are highly valued.

Using specialty glazes can sometimes cause glaze defects. But knowing the chemistry behind them can help avoid these problems. For example, crystalline glazes need specific firing conditions, like cone6, to form crystals.

The Science Behind Glaze Formation

The science of glaze formation is both fascinating and complex. It combines chemistry, materials science, and art. To understand glaze formation, we must explore the firing process, chemical reactions during firing, and the cooling phase’s effects.

The Firing Process Explained

The firing process is key in making ceramic glazes. It heats the ceramic to high temperatures in a kiln. This melts the glaze materials, creating a glassy layer. The kiln’s temperature and atmosphere are carefully set to get the right glaze properties.

Chemical Reactions During Firing

Many chemical reactions happen during firing. These reactions turn raw glaze materials into a strong, glass-like surface. They involve breaking down metal oxides and forming new compounds. Knowing these reactions helps control the glaze’s look.

Cooling Phase: Effects on Glaze

The cooling phase after firing is also vital. It shapes the glaze’s final look and feel. The cooling rate and kiln atmosphere can change the glaze’s color, texture, and strength. For example, slow cooling can create crystals, adding unique effects.

Understanding glaze formation’s science lets ceramic artists fine-tune their work. This knowledge helps create stunning, functional glazes. It enhances the beauty and use of ceramic pieces.

Colorants in Ceramic Glaze

Colorants are key to mastering ceramic glaze chemistry. They add colors and effects to glazes. Choosing between natural and synthetic colorants is important.

Natural vs. Synthetic Colorants

Natural colorants come from minerals and oxides found in nature. They’ve been used for centuries. Synthetic colorants, made by humans, offer more colors and consistent results. Mixing both can create unique glaze effects.

Common Metallic Oxides Used

Metallic oxides are common in ceramic glazes. Iron oxide can change from yellow to black with firing. Copper oxide can make greens, turquoise, and reds under different firing conditions. It’s all about how they mix with other glaze components.

Effects of Temperature on Color

Firing temperature greatly affects color. Different colorants react differently to heat. For example, some oxides change color with temperature. Knowing this helps achieve the right color.

In conclusion, choosing and using colorants in glazes needs a deep understanding. By mastering natural and synthetic colorants, artists can create a wide range of colors. This enhances their glaze-making skills.

Testing and Adjusting Glaze Recipes

To get the most out of your ceramic glazes, you need to test and adjust them well. This ensures your glazes look as you want them to. It also helps avoid glaze defects that can spoil a piece.

Importance of Testing in Glaze Chemistry

Testing is key in glaze formulation. It lets potters see how a glaze will act when fired. Without testing, even the best glaze plans can go wrong, leading to bad colors or textures.

By testing glaze recipes, artists can tweak them to get the look they want. This means applying the glaze to test tiles, firing them, and then checking the results. This helps figure out what changes are needed.

How to Make Adjustments

Adjusting a glaze recipe means knowing how each ingredient works. For example, if a glaze is too thin, adding more alumina can thicken it. If it’s too thick, a flux can help.

It’s important to keep track of each test and change made. This helps improve the glaze recipe over time and avoid making the same mistakes again.

Common Testing Methods

There are several ways to test glaze recipes:

- Applying glaze to test tiles to see how it acts when fired.

- Firing test pieces in a kiln to check the results.

- Doing chemical tests to understand the glaze’s makeup and how it will perform.

By using these testing methods and knowing a lot about glaze chemistry, artists can create unique and reliable glazes. These glazes can really make their work stand out.

Troubleshooting Common Glaze Issues

Glaze defects can be frustrating. Knowing what causes them is the first step to fixing them. Ceramic artists often face problems like crawling, blistering, and color issues that can spoil a piece.

Crawling and Blistering Problems

Crawling and blistering are common issues that can affect a ceramic piece’s look. Crawling happens when the glaze pulls away from the edges or certain areas of the ceramic body. This is often due to uneven drying or wrong glaze application. To avoid crawling, make sure the glaze is applied evenly and dry the piece slowly and carefully.

Blistering is usually caused by gases trapped under the glaze during firing. To reduce blistering, ensure the kiln is well-ventilated and the firing schedule is right for the glaze. Changing the firing schedule or improving kiln ventilation can help solve this problem.

Solving Color Inconsistencies

Color issues can be a big problem, aiming for a specific look. These problems can come from uneven glaze application, firing temperature variations, or using different raw materials. To get consistent colors, it’s important to keep the glaze application process the same and control the firing conditions well.

“Consistency in glaze application and firing conditions is key to achieving uniform colors in ceramic glazes.”

Understanding Glaze Fit

Glaze fit is how well the glaze sticks to and works with the ceramic body during firing. A good glaze fit is key to avoiding defects like cracking or shivering. The glaze and ceramic body’s thermal expansion should match closely for a good fit. Testing and adjusting glaze recipes can help find this balance.

By knowing the causes of common glaze problems and finding ways to fix them, ceramic artists can improve their work’s quality. Whether it’s changing how the glaze is applied, adjusting the firing schedule, or tweaking the glaze recipe, there are many solutions to glaze defects.

Safety Considerations in Ceramic Glaze Chemistry

Safety is key in ceramic glaze chemistry, affecting both the artist and the environment. Working with glazes means handling various materials, some of which can be dangerous if not handled right.

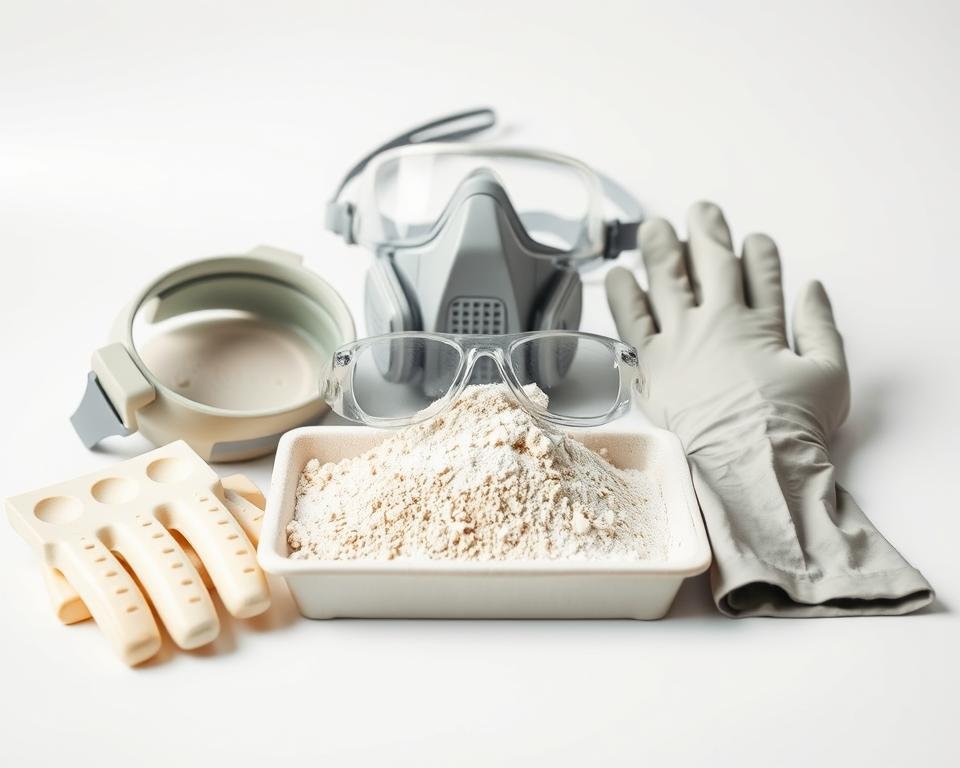

Handling Raw Materials Safely

Safe handling of raw materials is a big deal in ceramic glaze chemistry. Many glaze materials are powders that can become airborne and be inhaled, posing health risks. It’s important to store these materials in sealed containers and handle them in a way that minimizes dust generation.

- Use a dust mask or respirator when handling powdered glaze materials.

- Keep the workspace clean and free of dust to prevent the accumulation of potentially hazardous particles.

- Label all containers clearly to avoid accidental misuse of materials.

Proper Ventilation Practices

Good ventilation is key in a ceramic studio to remove airborne contaminants. This includes dust from dry materials and fumes from the firing process.

Make sure your studio has enough ventilation systems, including:

- Exhaust fans to remove fumes and particles.

- Ventilation hoods over work areas where chemicals are mixed or used.

- Regular maintenance of ventilation systems to ensure they are functioning correctly.

Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) is a vital part of safety in ceramic glaze chemistry. PPE includes gloves, safety glasses, and protective clothing.

| Type of PPE | Purpose | Recommendation |

|---|---|---|

| Gloves | Protect hands from chemicals | Nitrile or latex gloves |

| Safety Glasses | Protect eyes from splashes | Goggles or glasses with a wrap-around frame |

| Protective Clothing | Prevent skin contact with hazardous materials | Long-sleeved shirts and pants |

By focusing on safety and using the right protective measures, ceramic artists can reduce risks from glaze chemistry. It’s also important to know about the materials you’re using and follow best practices for handling and disposal.

Environmental Impact of Ceramic Glazes

Ceramic artists often forget about the environmental impact of their work, like glaze production. The truth is, making ceramic glazes can harm the environment a lot.

Sustainable Practices in Glaze Production

Using sustainable practices in making glazes is key to lessening harm to the environment. This means getting raw materials responsibly, cutting down on waste, and using less energy when firing.

Using local and recycled materials is a smart move. Some artists use waste like fly ash or recycled glass in their glazes. This cuts down on the need for new materials and lowers carbon emissions.

Reducing Waste and Pollution

To cut down on waste and pollution, several steps are important. First, measuring and mixing glaze ingredients accurately helps avoid waste. Also, recycling leftover glaze materials can greatly reduce landfill waste.

It’s also vital to have good ventilation in the workspace. This keeps artists safe from harmful fumes and particles. It also helps prevent pollutants from getting into the air and water.

Eco-friendly Material Alternatives

The search for eco-friendly material alternatives is leading to new ideas in ceramic glaze chemistry. Scientists are looking into natural, safe materials to replace harmful glaze components.

Some studios are now using plant-based and natural minerals for glazes. These are safer for artists and better for the planet. Moving towards eco-friendly glazes is a big step towards making ceramics more sustainable.

Innovations in Ceramic Glaze Chemistry

The world of ceramic glaze chemistry is changing fast. New discoveries are making it possible to create complex, high-quality glazes. These glazes were once thought to be impossible.

Advances in Glazing Technology

New glaze formulations are coming out, thanks to glazing technology advancements. Nanotechnology is being used to make glazes with special properties. For example, self-cleaning surfaces and better color retention are now possible.

A study on ceramic glaze research shows these changes are big for the industry.

3D Printing and Glaze Chemistry

3D printing is changing how we work with ceramic glazes. It lets us make complex shapes and designs. This is because 3D printing can apply glazes with great precision.

For instance, it can make ceramic parts with specific glaze needs, like cone6 glazes. These glazes are fired at a lower temperature.

Future Trends to Watch

The field is set to keep evolving. We can expect more eco-friendly glaze materials and digital tools to improve glazing. There will also be new glaze effects from advanced materials and technologies.

By keeping up with these trends, artists and manufacturers can innovate further. They can explore new possibilities with ceramic glazes.

Conclusion: Mastering Ceramic Glaze Chemistry

Exploring Ceramic Glaze Chemistry shows us how vital it is to know about glaze composition and science. This knowledge helps artists get the results they want in their ceramic work.

Key Takeaways

Our journey into Ceramic Glaze Chemistry has shown us the importance of making glazes. We’ve learned about the parts that make up glazes and how firing affects them. This knowledge lets artists control their work better.

Experimentation and Further Learning

I suggest trying out different glaze recipes. This way, you can see all the possibilities in Ceramic Glaze Chemistry. There are many resources out there, like online tutorials, workshops, and books, for those who want to learn more.

Keep exploring and learning about Ceramic Glaze Chemistry to improve your craft. It doesn’t matter if you’re experienced or just starting out. The world of glaze making is full of chances for creativity and new ideas.